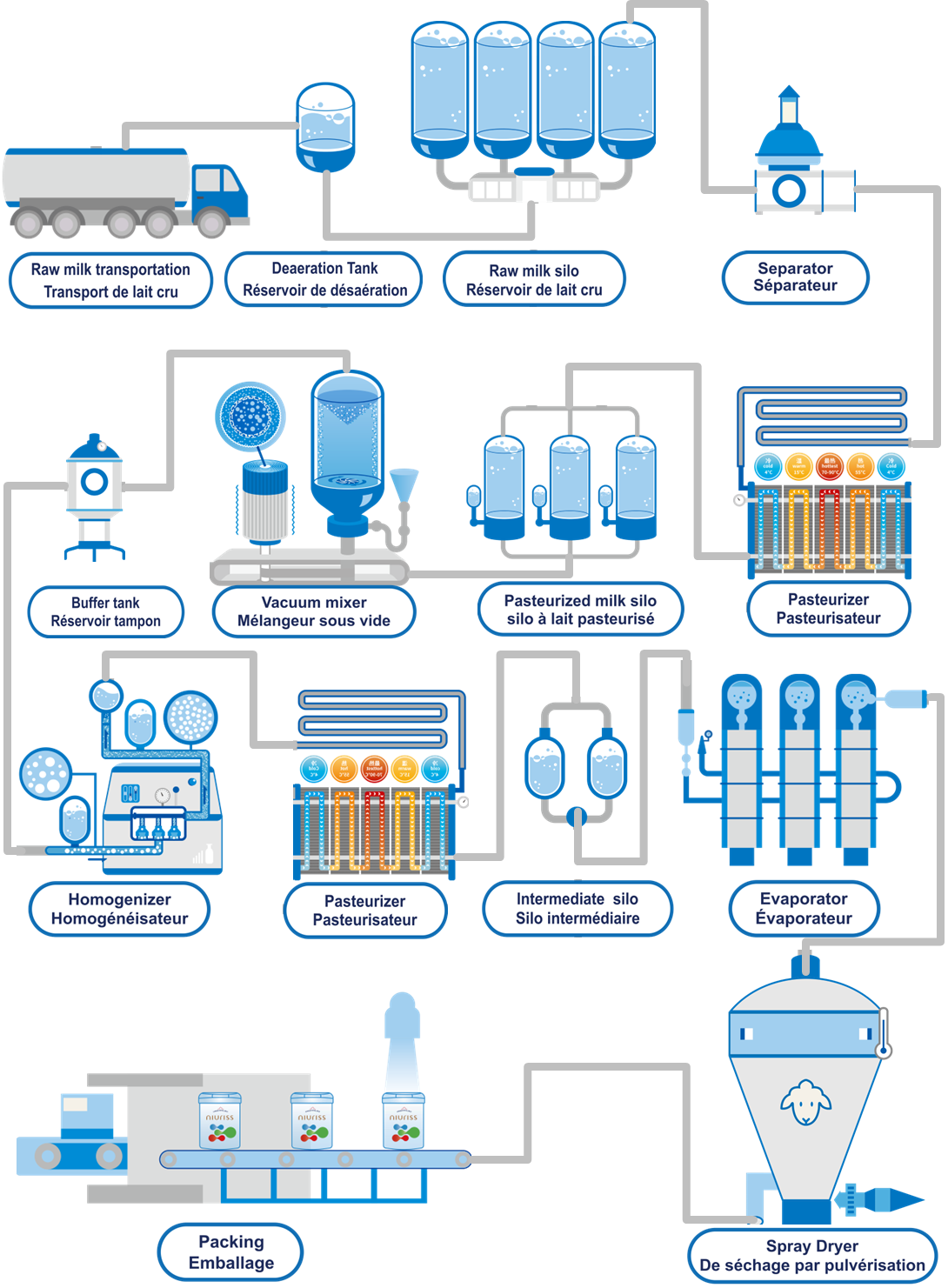

PRODUCTION FACILITY

As one of the only milk powder manufacturing facilities in Canada, CRM uses state-of-the-art equipment, managed by highly-trained professionals, to manufacture some of the world’s leading infant formula and milk formula products.

Three lines of receiving system, with two

having a loading capacity of 60 tons per

hour each and the third one having a loading

capacity of 30 tons per hour.

The system includes two pre-treatment pasteurization lines,

The system includes two pre-treatment pasteurization lines,

each with a capacity of 30 tons per hour, as well as a cream

pasteurization line capable of processing 5 tons per hour.

Two independent vacuum mixing lines,

each with a mixing capacity of 30 tons per hour,

as well as two ingredient pasteurization lines,

each capable of processing 30 tons per hour.

Four sets of three-effect falling film evaporators,

with two of them dedicated to each drying tower to

ensure continuous operation, and each evaporator

possessing an evaporating capacity of 11 tons per hour.

Two separate dry mixing lines, each with

a capacity of 6 tons per hour, along with

eight spacious powder silos, each boasting

a volume of 33 cubic meters.

Three Filling & packaging lines: 25kg paper

bag bulk line, 900g tin-can PLF line, and

300g tin-can line.